Grinder, also called coffee grinder, is an important electrical product in the life welfare of modern family life and office. The coffee machine DC motor is one of the core components of the grinder, which directly affects the taste and quality of coffee production. This article will introduce the coffee machine DC motor customization plan for readers in detail from the aspects of motor selection, safety guarantee, motor installation test, customer use effect evaluation and adjustment, etc.

The coffee machine DC motor is one of the core components of the grinder, which directly affects the taste and quality of coffee production. This article will introduce the coffee machine DC motor customization plan for readers in detail from the aspects of motor selection, safety guarantee, motor installation test, customer use effect evaluation and adjustment, etc.

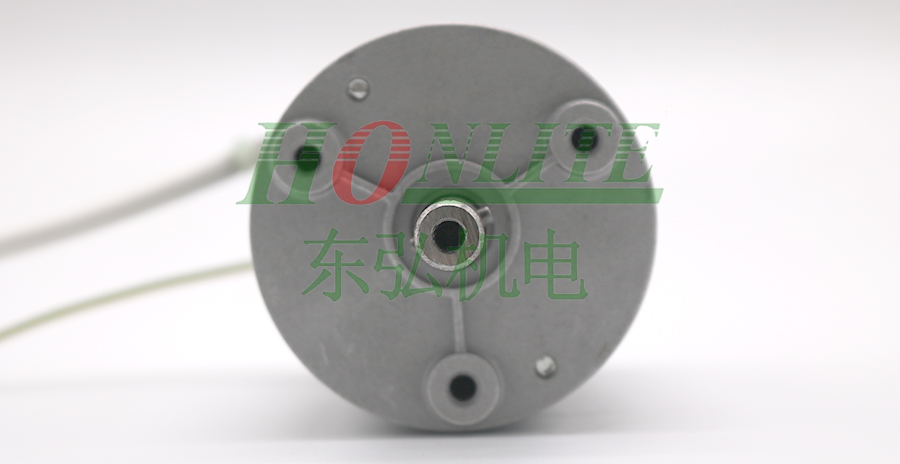

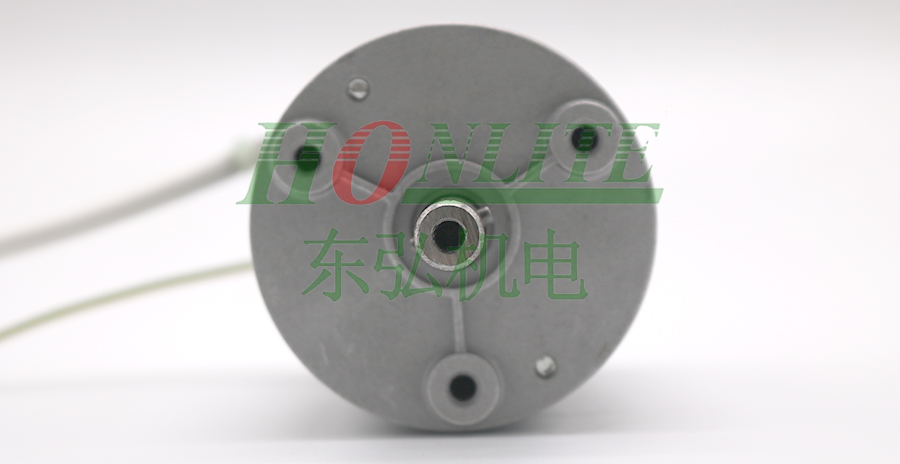

1. D53 DC motor selection and parameters:

The selection of the coffee machine DC motor is one of the keys to the customized solution. According to usage scenarios and requirements, it is necessary to select appropriate parameters such as power, speed, and voltage. Generally speaking, the higher the power, the faster the speed and the higher the voltage, the better the performance of the motor. In this case, we chose a D53 DC motor with a power of 300W, a speed of 5000-6000rpm/min, and a voltage of 220V.

2. Manufacturing safety guarantee:

The D53 DC motor uses components and materials that meet UL certification standards, making the motor have a safe and stable foundation. Process the production process and conduct multiple tests to ensure that the factory is qualified. This motor is equipped with a temperature controller, which can realize automatic temperature control or manual temperature control management, and automatically or manually trip when the set temperature is reached. This motor can be tested for stalling according to customer needs, and can be protected at different levels such as B-level, F-level, and H-level.

3. Strict motor installation and debugging:

The installation of the DC motor of the coffee machine needs to be carried out in strict accordance with the instructions to ensure that the motor is installed on a stable ground to prevent excessive vibration and noise of the motor. During the installation process, it is necessary to pay attention to the positive and negative polarity of the wiring of the motor and the connector to prevent short circuit and leakage of the motor. Before commissioning the motor, it is necessary to perform a performance test and verification on the motor to ensure that the motor is operating normally, and we will provide customers with sufficient suggestions.

4. Customer use effect evaluation and adjustment:

The evaluation of the use effect of the DC motor of the coffee machine is a key link to ensure the taste and quality of coffee. We evaluate the performance of the motor through the actual use data of the customer, analyze its advantages and disadvantages, provide a basis for subsequent improvement, and cooperate with the customer to adjust the motor. At the same time, we also tested the service life of the motor to ensure that the service life of the motor meets expectations.

Summarize:

Customizing a DC motor for a coffee machine is a complex process that requires consideration of multiple factors. By selecting the appropriate motor model parameters, manufacturing safety assurance, strict installation and commissioning, and customer use effect evaluation, we can ensure that the performance and quality of the coffee machine DC motor meet customer needs.

Insulation class: ClassB

Telephone: 0769-86637398- 223

Phone: 86-13450675746

WeChat: 86-13450675746

Fax: 0769-86638487

E-mail:watson@honlite.com.cn

Address: Xin wei li canton, Liu wu Industrial Area, She kit town, Dongguan city, Guangdong province,China